Hebei Yuandong Pumps Manufacturing Co., Ltd.

+86 22 88492093

+86 18333723076

hbydby@126.com

No.88 Daodong Street,Botou,Cangzhou,Hebei Province,China

Pumped liquid:

fuel oils, lube oils, hydraulic oils, cutting oils, coolant oils, cooling oils, waxes, tar oils

Main fields of application:

Firing, hydraulics, mechanical engineering, general industrial technologies, chemical and petrochemical industries, marine and offshore engineering

Performance data Series 3G:

Figure | construction form | main application | Specifications | |

Capacity | Max. pressure | |||

3G 3GC | single suction horizontal installation | Lub oil or lub liquid visc 20-150cst | 0.3-94(m3/h) | 60(bar) |

3GS 3GCS | Double suction horizontal installation | 80-590 | 16 | |

3GCG | single suction hanginginstal tation | 10-96 | 8 | |

2GCL | Single suction vertical pedestal | 4--96 | 8 | |

3GCLS | Double suction vertical pedestal | 88-306 | 8 | |

3Gr 3GCr | single suction horizontal installation | Lingt oil or heavy oil visc 3-365cst | 0.3-94 | 60 |

25 | ||||

3GSr 3GCSr | Double suction horizontal installation | 80-590 | 16 | |

3GN | single suction horizontal installation | hing visc. fuel oil visc 365-760cst | 1.0-40 | 25 |

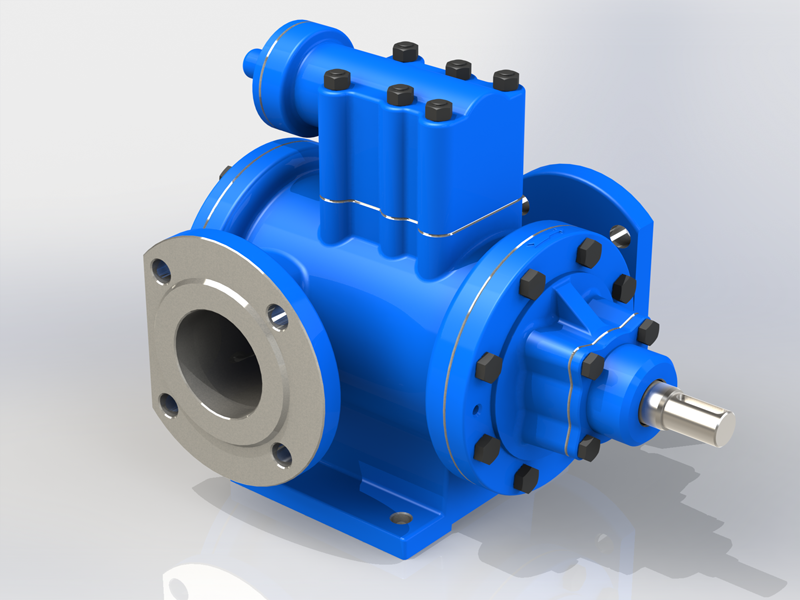

1. Simple in construction: The pump has quite a few construction forms. General for small flow

range 0.2-6.5m3/h, pump casing and insert is made in one part. Mechanical seal is used as the pump shaft seal.

Pumps of middle and big flow range have a separate insert to be fixed in side the pump

casing .Big pumps are mostly of a double –suction design for horizontal installation. For different mediums to be pumped mechanical seals or packing seals could be supplied.

For marine application pumps, installation forms could be horizontal and vertical , with marine AC and DC drivers.

2.Long life time: As the drive screw is driven by motor and there is no mechanical contact between the drive screw and the idler screws; the idler screw are hydraulically driven by the pressured liquid; between the drive screw and idler screw, screws set and insert an oil film is formed, so the mechanical friction is minimized and a longer life is ensured.

3. The medium to be pumped is in a manner of constant axial flow movement, so the pressure pulsation is almost eliminated, meanwhile the noise is lowered; and as the moving parts have a very little inertia, the starting torque and vibration is very little.

4. Pump have a very high suction capability.

5. In order to ensure the safe working of pump, motor, piping system, pumps for a capacity higher than middle flow range are all equipped with safety valves. When working pressure is exceeding the setting pressure of valves, pressured oil will circulate back to suction chamber.

Period!